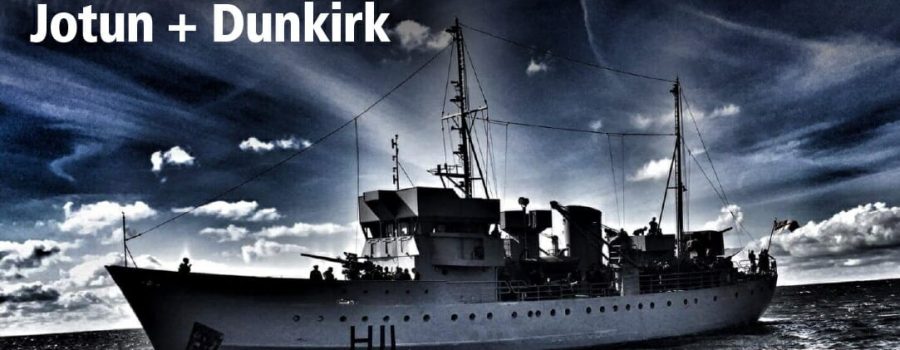

Last summer, the major motion picture ’Dunkirk’ featured two vessels coated by Jotun. The D/S Rogaland, a steamship completed in 1929, was re-painted to mimic a World War II hospital ship with coatings donated by Jotun. The second, MLV Castor, was constructed by the Dutch Royal Navy in 1950 and has a rich history. While neither vessel won an Academy Award, we take pride in Jotun’s support for historic vessels!Jotun is a leading provider of coating solutions to the global marine fleet. Jotuns Hull Performance Solutions is unique – with a new and transparent way of measuring hull performance along with a guaranteed maximum speed loss. Jotuns anti-fouling solutions are regarded as the best in the market – which along with our Onboard Maintenance Solution with products such as Jotamastic and Hardtop offer significant cost saving for the shipping industry.

Smart Pack System – Jotamastic Smart Pack and Hardtop Smart Pack – is specially designed for brush and roller application and can reduce paint consumption with up to 50%.

To optimise your onboard maintenance, Jotun can support you with fit-for-purpose seastock products, training of crew, onboard maintenance manuals, a worldwide delivery network and a service for reviewing your purchasing behaviour.

The benefits of Jotun’s success in the marine industry are mirrored in yachting both megayachts and leisure yachts. Every Jotun product is the result of intensive research and development combining state-of-the-art technology with innovative thinking, practical knowledge and experience. Jotun offers much more than paint – a combination of enthusiasm, creativity and commitment that is unrivaled in the yacht industry.

Onboard maintenance is often carried out at short notice without a great deal of planning. This may lead to an insufficient coating result. By having a well planned and executed Onboard Maintenance Program, the appearance and the performance of the coating will meet your expectations. As a result, maintenance intervals will be longer and the vessel will have a better cosmetic appearance throughout its lifetime. Long term paint consumption and maintenance cost will be reduced and the crew will spend less time on paint jobs. Ultimately, vessel lifetime can be prolonged and cost during dry-docking will be reduced.

Preparation & Application Guide

Leave a Reply

Your email is safe with us.